Home > Tennessee > Tennessee Crops & Livestock > Tennessee Meat Industry: Steamlining the Process

Tennessee Meat Industry: Steamlining the Process

In partnership with: Tennessee Department of Agriculture

Consumer interest in locally grown food has created opportunities for small farms to raise and sell their own meat products, but processing and packaging for sale has been the missing link. That’s changing in Tennessee.

“We’ve had producers in the state who want to sell meat from their farm or at farmers markets and in retail stores, but there’s been a bottleneck in the processing,” says Wendy Sneed, livestock marketing specialist with the Tennessee Department of Agriculture. “In order to sell meat to a retail outlet or individual customer, a producer must use a USDA meat processor. That’s been an issue because existing certified processing facilities are already running at full capacity, processing products for their own products and longtime customers.”

Enter Southern Natural Foods, Niko & Company and Blankenship Farms – three processors that now serve small farming operations.

Niko & Co., located in Walling (Middle Tennessee), and Blankenship Farms in Calhoun (East Tennessee) are new processors. Both families saw a need for additional processing facilities for themselves and neighboring producers and seized the opportunity to help grow their local, rural economies.

Niko processes poultry, including small flocks, for independent growers. Blankenship Farms processes beef and pork, while Southern Natural Foods took over an existing facility in Lexington (West Tennessee) and processes beef for independent farmers as well as to market under its own label.

All three companies received assistance from the Tennessee Agricultural Enhancement Program with the goal of providing expanded processing opportunities for the state’s livestock producers. TAEP is a state cost share program designed to help producers make long-term investments to improve efficiency and profitability.

Other processors in the state are expanding on their own, including H&P Meats in South Pittsburg, which has almost doubled in capacity over the past year. Additional processors mean small farmers have an improved opportunity to sell their own products.

“Not every producer is going to want to participate in a niche market, but for those who do, these processors make that available to them,” Sneed says. “Farmers have a chance to brand their products and tell their story.”

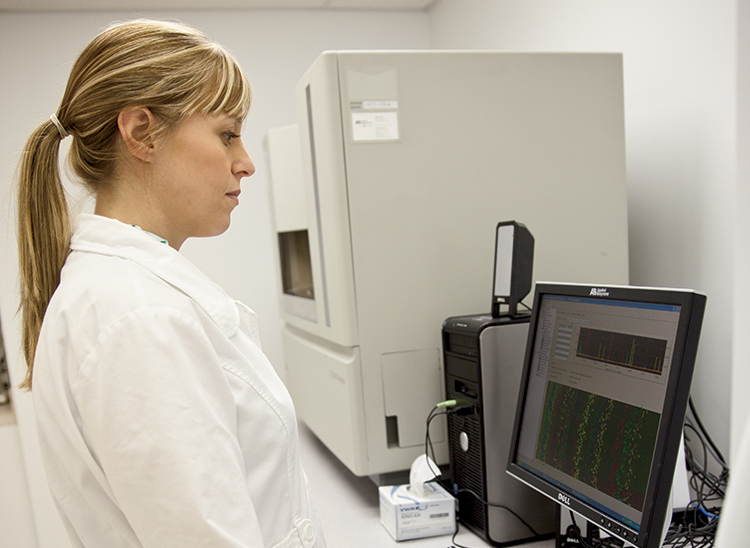

Southern Natural Foods is taking that branding concept to a new level. Southern Natural has partnered with BioPet Vet Lab to implement the IntegriMEAT program, which uses DNA testing and tracking to verify the origin and quality of beef products – and puts that information in the hands of consumers.

With new descriptive labels like grass-fed, organic, hormone-free, or free range, navigating the meat counter in a grocery store or even a menu in a high end restaurant can be challenging, which is where BioPet’s IntegriMEAT program comes in.

“When you pay the extra $3 per pound for grass-fed beef at the market or a premium price in a restaurant, how confident are you in the origin of the meat?” asks BioPet Vet Lab CEO Tom Boyd. “DNA is the only way to verify the source of the meat. We can track beef from the ranch to the processor to the retailer.”

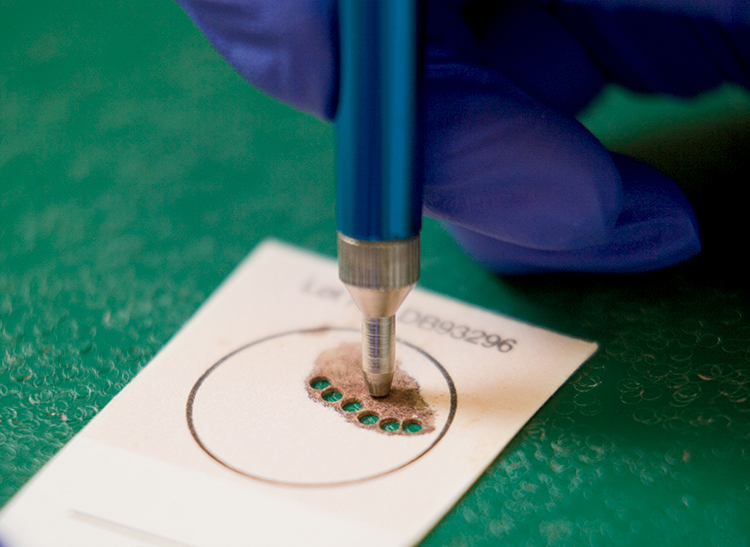

IntegriMEAT begins with a simple DNA field collection of a few drops of blood onto a provided stabilizing paper. Ideally, this is not collected early in the calf’s life but typically during ear tagging. The DNA results are entered into a database that tracks the beef up to the point of purchase by consumers.

To put this information into consumers’ hands, BioPet Vet Lab has partnered with Southern Natural Foods. A unique Quick Response (QR) code is affixed to each package of meat, giving a consumer product information at the point of sale. Each QR code is linked to the farm profile providing the exact origin of the cut of beef, feed type, breed influence, farm history and farm commitments. Each farm’s profile will also inform the consumer of any beef recalls or food safety warnings associated with that producer.

Boyd says the DNA tracking system raises consumer confidence and also adds to the value of the products, which will result in additional sales taxes for the state and additional revenue for the producers. Plus, DNA tracking helps identify which bulls owned by the producer sire the highest quality calves – information producers can use to increase profits.

DNA tracking also has direct food safety benefits. Tracing of food sources throughout the supply chain allows targeted responses and rapid response times for recalls during food safety occurrences. Tracking makes it possible to isolate and resolve contamination sources.

“We would like to see all of Tennessee’s retail producers participate in this program,” Boyd says. “We should be the first state to have 100 percent verified beef.”

Boyd predicts the program will give Tennessee an edge in the international market.

“The export market is an important source of revenue for Tennessee producers,” he says. “With DNA tracking, Tennessee can assure international customers of the quality they are getting. That could make our state’s products some of the most trusted in the world.”