Home > Tennessee > Tennessee Crops & Livestock > Growing Trees Grows Tennessee

Growing Trees Grows Tennessee

In partnership with: Tennessee Department of Agriculture

As master logger for the ProMark sawmill in Middle Tennessee, Bob Hughes is something of an authority on drumsticks.

He knows that white hickory is the best kind of wood for making drumsticks, and he’s the go-to person for scaling the logs and making sure they’re graded properly. And when he’s asked, he’ll tell people the world always needs drumsticks.

“I’ve been asked a million times, ‘What do you do with 60,000 drumsticks a week?’ I tell them that 60,000 is not even touching the demand. There are a lot of drummers in bands, college and high school bands, even just kids playing at home. I bought my grandson a drum set for Christmas.”

Located just north of the Tennessee-Alabama state line in Prospect, ProMark is a subsidiary of D’Addario, a New York based company that manufactures a variety of parts for musical instruments. The ProMark mill provides the first – and most critical – step in the process of making D’Addario’s drumsticks. After the lumber is sawed into the basic shape, the dowels are shipped for completion to a plant in Houston.

“We’re working real hard on the quality of our products,” Hughes says.

Driving the Economy

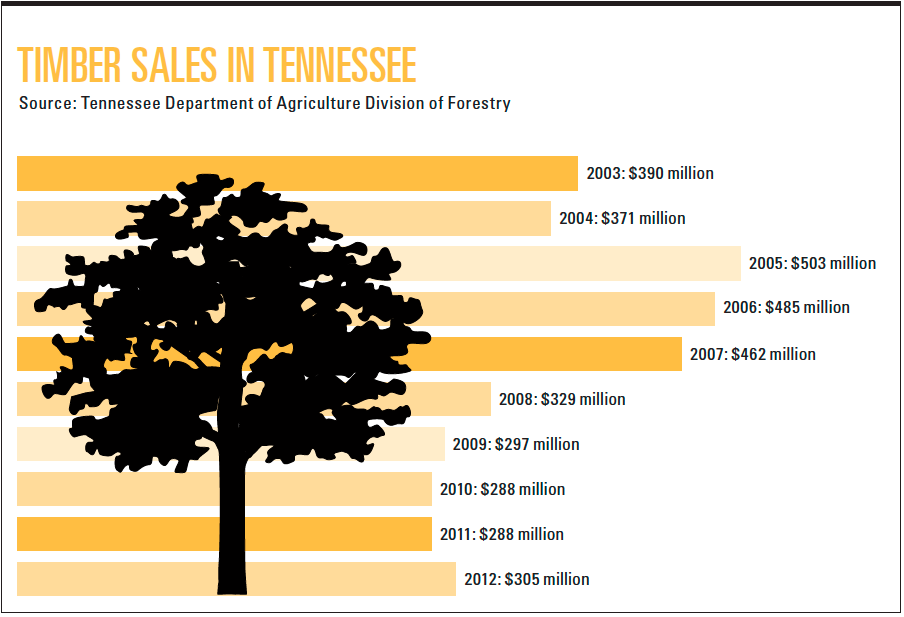

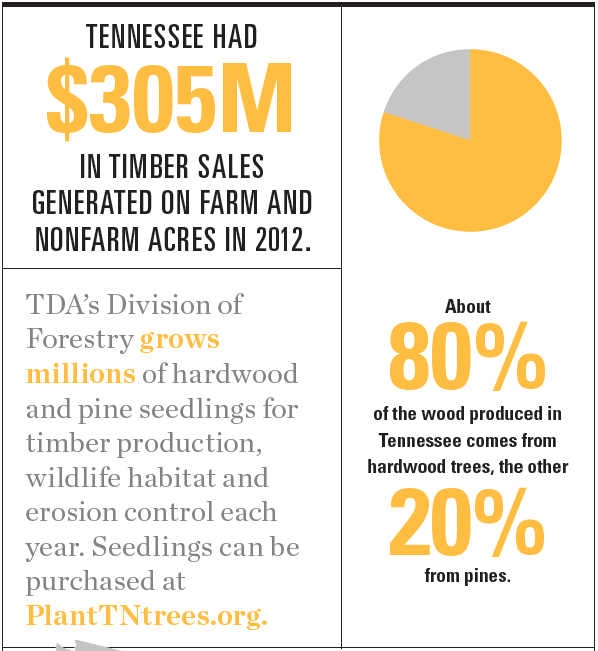

ProMark is just one example of how wood processors and paper mills contribute to the overall strength of Tennessee’s forest industry, which generated about $305 million in timber sales in 2012 and has a $21 billion impact on the state’s economy.

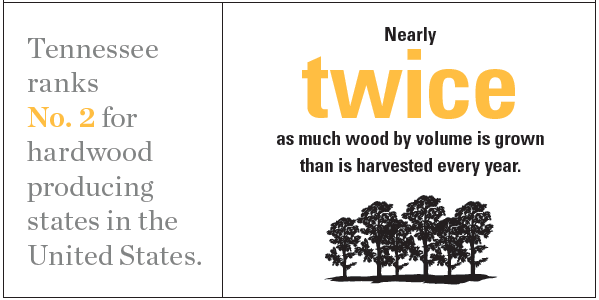

“Tennessee is a hardwood state above and beyond anything in terms of wood products,” says Tim Phelps, forestry communications and outreach unit leader for the Tennessee Department of Agriculture’s Division of Forestry. “About 80 percent of the wood produced in Tennessee comes from hardwood trees, the other 20 percent from pines. All wood using industries help to drive the economy of Tennessee, providing jobs for rural Tennesseans and products that we all use on a daily basis.”

The economic impact from an individual processor can be felt throughout a county or even a region.

“We’re buying logs from the immediate area as well as all over central Tennessee,” Hughes says.

Forest related companies are also major employers in some places. That’s the case for the Hassell and Hughes Lumber Company, which was founded in 1939 in Collinwood and today has around 140 employees.

“We are the third largest private employer in Wayne County and the largest industrial employer,” says Johnny Heard, a forester with the company.

On about 13,000 acres of land that’s primarily hardwood trees, Hassell and Hughes produces manufactured hardwood lumber, unfinished flooring and semifinished furniture. Its saw mill produces about nine million feet of lumber a year, according to Heard, using mostly red and white oak.

A Green Industry

Both ProMark and Hassell and Hughes have taken steps to promote just how “green” the Tennessee forest industry is.

“Our owner, Jim D’Addario, is very much a green advocate,” Hughes says. “He’s all about reforestation and the restoration of natural resources.”

As a result, ProMark has recently entered a partnership with TDA’s Division of Forestry to launch a tree planting program. It’s an initiative aimed at ensuring that the hardwood resources used for making drumsticks in Tennessee are sustainable.

Seedlings used for this program are grown at the division’s East Tennessee nursery in Delano and are provided at no cost to eligible Tennessee landowners. Since the 1950s, the division’s reforestation program has produced more than one billion tree seedlings, which help supply the raw materials needed to support Tennessee’s forest products industry.

Toward their environmentally friendly focus, Hassell and Hughes has turned what was once a waste product – primarily leftover wood shavings from the floor – and created a subsidiary known as Greenway Premium Wood Fuel Pellets. The plant produces around 15,000 tons each year of the pellets, which are used mostly in residential heating stoves.